When compared to conventional plastics made out of fossil fuels, bioplastics definitely have an upper hand in terms of environmental impact. But there are still some shortcomings associated with these materials, one of them being their low stability when subjected to high temperatures. Thanks to scientists at the University of Akron though this may soon no longer be a problem.

Looking to replicate conventional plastic’s stability to high temperatures, the researchers have managed to engineer a new form of bioplastic that could be used as a sustainable packaging option for hot takeaway food, something currently available bioplastics aren’t suitable for.

To do that, the team focused on a common form of bioplastic called polylactic acid (PLA), which is cheap to produce and a popular choice for things like food packaging and plastic bottles. Its main weakness though is that it quickly deforms when exposed to high temperatures.

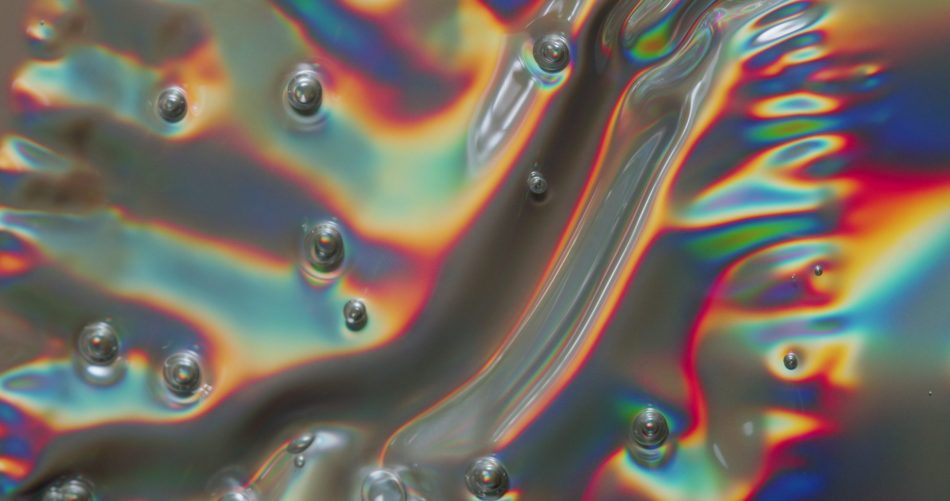

Led by Dr. Shi-Qing Wang, the research team involved in the new study has targeted this problem by reimagining the complex molecular structure underlying PLA plastics. Wang likens it to a bunch of spaghetti, with the chain-like molecules making up the plastic representing the individual noodles.

As New Atlas further elaborates, the toughness of the plastic depends on how intertwined these noodles are. By tweaking the way crystals form and limiting them to nanoscale in size, the scientists were able to create a highly interwoven “chain network” of these noodles, enabling them to produce a PLA plastic that is though, clear, and heat resistant.

To showcase the material’s impressive properties, the scientists fashioned the material into a prototype cup that could withstand boiling water without shrinking, degrading, or turning opaque. According to the team, such containers could be used as more environmentally friendly options for takeaway food and hot beverages like tea and coffee.

While bioplastics won’t solve the plastic crisis menacing our oceans, having a wider range of sustainable alternatives to single-use plastics could help minimize the material’s impact on the environment.